Fluid power systems transfer and utilise mechanical power through a working fluid. Energy is transmitted, stored and used through the transfer and pressure of fluids. By utilising differential surface areas acted upon by the pressure of the working fluid, a mechanical advantage can be achieved. There are two main types of fluid power systems:

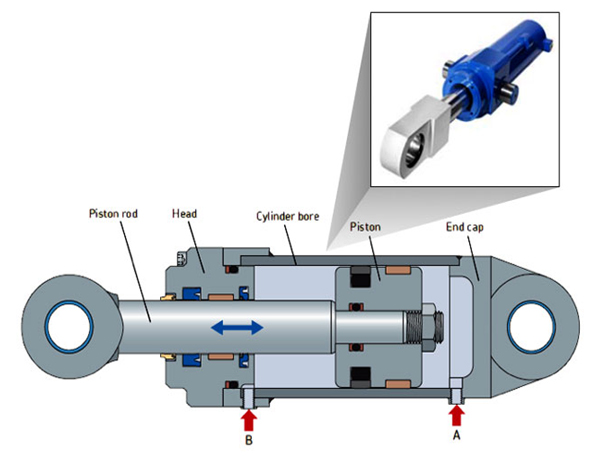

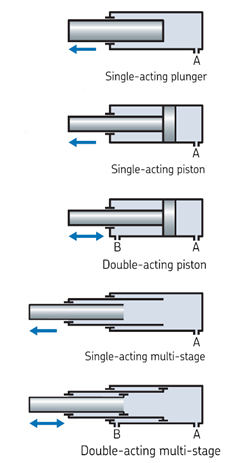

A hydraulic cylinder is a linear actuator used to push or pull a load, or to selectively resist motion under load by means of fluid pressure. Double-acting cylinders, the most common type, are able to push and pull (see Fig.1). High pressure fluid is pumped into the extend chamber port (Fig.1: A) and acts on the piston to push the piston rod out, thereby extending the length of the cylinder. Inversely, to retract the piston rod and reduce the length of the assembly, high pressure fluid is pumped into the retract chamber port (Fig.1: B) and acts on the opposite side of the piston.

A cylinder which can only push but not pull is referred to as a single-acting cylinder. High pressure fluid is pumped into the extend chamber (Fig.2: A) and acts on the piston to push the piston rod out. An external force is required to return the cylinder to the retracted position. A typical single-acting cylinder can be found on a forklift truck where the load of the fork assembly (tines and carriage) enacted by gravity pushes the cylinder back into the retracted position. Multi-stage cylinders (also referred to as telescopic cylinders) have two or more piston rods in a coaxial arrangement to achieve a greater extended length compared to the retracted length.

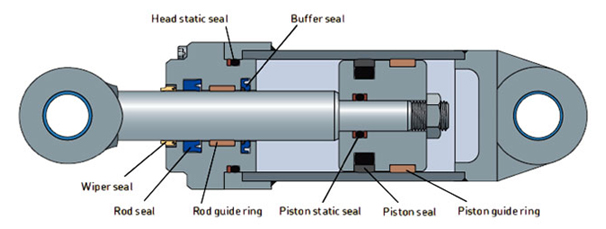

The type of cylinder and the application in which it’s used are two of the main criteria to determine which seals and guides are selected. Applications are referred to as light duty, medium duty and heavy duty. These classifications are somewhat subjective but the duty levels are typically characterised by the following criteria.

Light duty cylinders are typically cylinders used for stationary equipment, indoors in a factory environment and may be characterised by:

Medium duty cylinders are typically used in agriculture, off-highway equipment and may be characterised by:

Heavy duty cylinders are typically used in off-highway earthmoving, mining and forestry equipment and may be characterised by:

Hydraulic cylinder seals are used to seal the opening (clearance gap) between various components in the hydraulic cylinder. Fig.3 shows an example of the seal and guide components of a heavy duty cylinder.

There are two main types of hydraulic seals in the system:

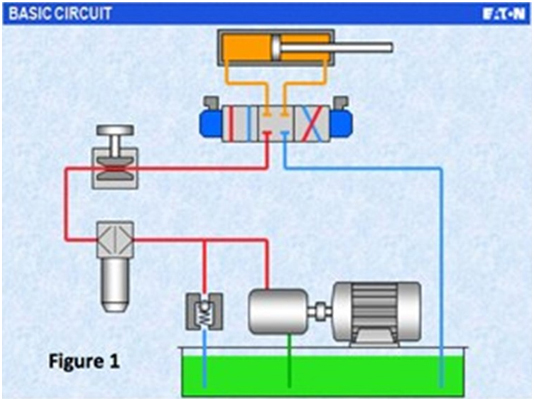

Hydraulic cylinders are used to convert hydraulic power into linear motion. The amount of force a hydraulic cylinder can exert is a function of the piston area and the hydraulic pressure. This is represented by the formula:

Hydraulic Cylinder Basic CircuitF = P x A where

F = force in Newtons (N)

P = pressure in Pascals (Pa)

A = area in square meters (m2)

A basic circuit to drive a hydraulic cylinder is shown in figure 1.

When a double acting hydraulic cylinder is extending the oil pressure acts on the total piston area, however when the cylinder is retracting the area available is the piston less the rod. Therefore for the same pressure the hydraulic cylinder extending force will always be greater than the retracting force.